CLIMATE

On earth, every plant mass benefits abundantly from air rich in CO² (carbon dioxide or carbon dioxide) and O² (oxygen). Without this, all life is impossible! Through the stomata covering their leaves (similar to human pores), a plant rejects oxygen (but also consumes some, but less!!!) and assimilates CO² (but also rejects some, but less!).

From this state of affairs, indoors, the fact of reproducing the climatic conditions as close as possible to the outside guarantees abundant and rapid harvests.

Plants produce their own organic matter (sugar, cellulose, energy...) from water (mineral salts) and CO², assimilated by the leaves thanks to solar energy; this is the photosynthesis mechanism. Without this gas, the plant dies. Through the stomata covering their leaves, plants release more oxygen than they consume and consume much more CO² than they release. Indoors, none of the natural elements that generate CO² are present, except the plant. It is the horticulturist who must take care to bring it to him.

Air extractors and intractors

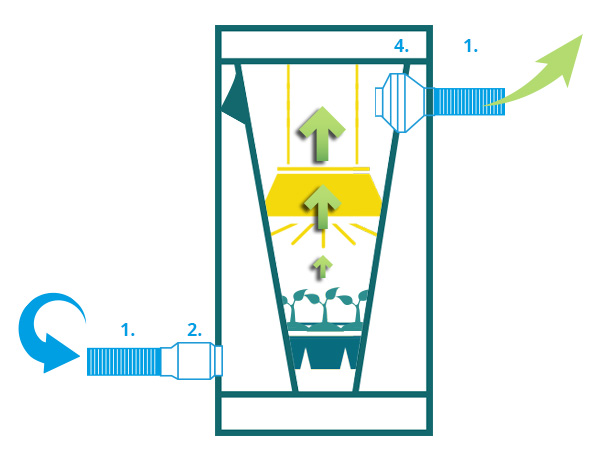

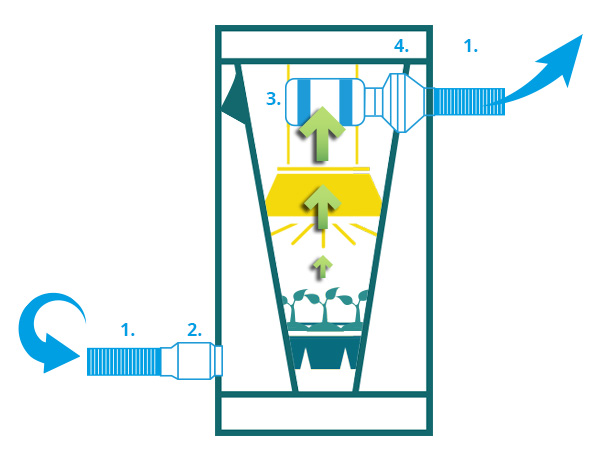

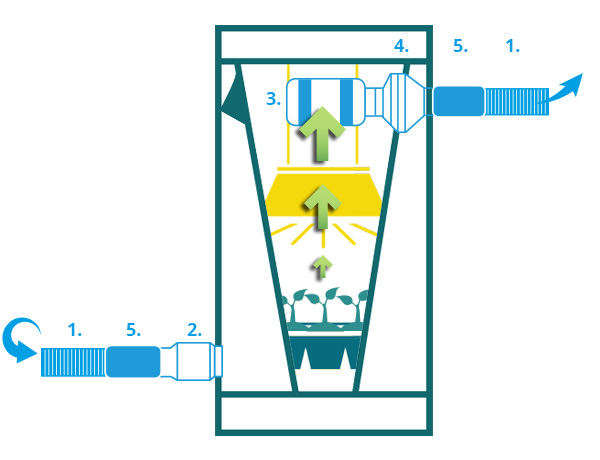

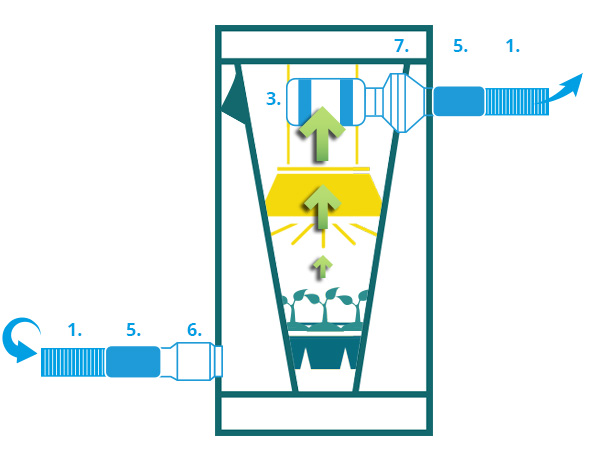

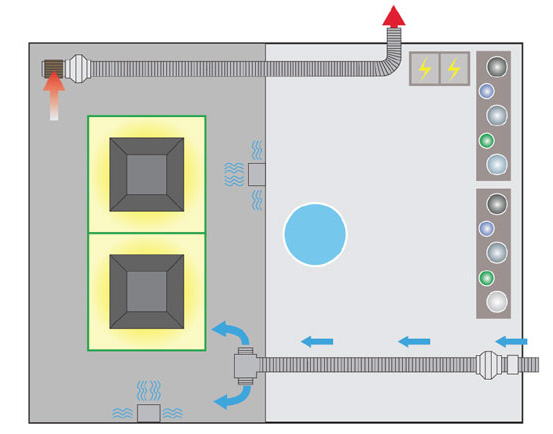

A extractor and an air intractor are essential in a culture chamber, working by air intake. The extractor, placed in height, renews the CO² and ejects the impoverished air of the culture chamber, while regulating the temperature. The intractor facilitates the work of the extractor by optimizing air renewal; it is placed at the bottom of the room, opposite the extractor and at a lower speed. The power of these two turbines must be proportional to the heat released by the light sources used, depending on the growing area.

The air extractor evacuates the hot and oxygen-depleted air from the growing rooms. It is essential in indoor cultivation because it avoids the suffocation of plants and the attack of parasites and molds that love stagnant and humid air. Reverse the direction and you will obtain an air intravenous.

All you need to know to control the air

Ventilation |

Temperature |

|

In addition to air renewal, ventilation is an essential parameter for the proper functioning of a growing room. The air movements facilitate the 0²/CO² exchanges of the stomata (= gain of vivacity) and widen the plant structure (= gain of production). They are ensured by fans they are ensured by air blowers, to be directed directly on the plants in a homogeneous and progressive way. |

The required temperature is between 20°C and 25°C, ideally 23°C. Thanks to extraction/intraction and ventilation, the temperature of the grow room is controlled to a certain extent; indeed, maintaining a good temperature is difficult in summer when the ambient heat is added to that of the lamps. Two solutions: use an air conditioner or switch on the lighting phase at dusk. It is important that the temperature variations do not exceed 10°C between day and night to avoid any stress on the plants. It is advisable to connect a thermostat to the extractor and the intractor in order to automatically manage the temperature variations within the growing room. Moreover, it is important that the temperature variations do not exceed 10°C between the day and night phases to avoid any unnecessary stress on the plants. To avoid these disturbing fluctuations, it is advisable to connect to the extractor and the introducer a thermostat, a device allowing an automated management of the temperature within the culture space. See the heating category. |

Moisture |

Odors |

| In addition to temperature control, the use of extractors/intractors and fans allows for humidity (or hygrometry) control. Expressed in percentage (%), the quantity of water available in the air is measured with a hygrometer and controlled by a hygrostat (coupled with the extraction/ventilation or humidification). In most cases, a growing room housing plants in vegetative phase (growth) requires the installation of a humidifier (cold vapor and preferably already equipped with a hygrostat) or an ultrasonic fogger to maintain the 50 to 70% of hygrometry necessary. These measures guarantee optimal gas exchanges at the level of the stomata. On the other hand, 45 to 50% relative humidity is sufficient for flowering, to avoid possible molds. A thermo-hygrometer measures the temperature and humidity, and can display the minimum/maximum of these values. This very practical tool is to be placed in the center of the cultivation space and at the height of the top of the plants in order to record the right data. These two measurements, temperature and humidity, are combined on a device that can display the minimum/maximum of these two values, the thermo-hygrometer. This very practical tool is to be placed in the center of the cultivation space and at the height of the tops of the plants to record the real measurements. |

Odor management is also a factor to consider in order not to disturb the neighborhood. For this, several products available on the market are up to 100% effective: the carbon filter, the ionizer (a device that releases negative ions that clean the air) or the ozone generator (requiring the installation of an additional chamber to place the generator). The carbon filter, the ionizer (a device that releases negative ions to eliminate odors and clean the air) or the ozone generator (requiring the installation of an additional chamber to place the generator). Being the most sold and the best quality/price ratio, the carbon filter is a large cylinder filled with activated carbon trapping odors. Very simple to install, it is placed at the top, inside the growing space and connects to the inlet of the extraction circuit as the heat and odors rise. In addition, placing a charcoal filter outside at the entrance of the introduction circuit (flexible filters of the Odorsok type are recommended for this purpose) also guarantees the absence of intrusions of pests, dust and/or unpleasant odors on the fruits or flowers that could come from the environment near the growing room. |

CO² injection |

Soundproof boxes |

| In order to boost plant growth and maximize production, some demanding growers resort to CO² injection. This technique consists in releasing carbon dioxide within the culture chamber which must be hermetic (installation of non-return valves at the air inlets/outlets) to reach a value of 1500 ppm. This supply can be done efficiently in two forms: melting of dry ice (placed in containers) or controlled release of CO2 tanks (connected to a solenoid valve and a CO2 controller informed by a probe). In order to prevent carbon dioxide poisoning, the installation of a CO² detection alarm is strongly recommended. |

The soundproof boxesthe soundproof boxes allow to stop the noise of some ventilation equipments.

|

Selection of ventilation equipment

The ventilation of your growing room has 2 important factors: the removal of warm air (depleted in CO2) and the entry of new fresh air. The warm air is removed using a VK series air extractor. The fresh air can either be supplied by passive ventilation (open window type) or by the installation of an air intake unit of the TT series, which can also be used as an extractor. Knowing the size of the room and the number of lamps that will be used, you can work out the required ventilation in m3 per hour (m³/h)

How to calculate the size Ø and the extraction rate of the fan m³/h :

First of all you have to calculate the size of the fan needed. There are several ways to determine the desired extraction power depending on the volume of the room. Some are more appropriate than others and some are more complicated. The following method is well known and has been approved by many growers:

[Extractors: exhaust required at fan capacity (m³/h)]

= [Volume of active growing area (m³) x air change per unit time (hours) x [Rate loss - Charcoal filter]

NOTE: When we talk about growing volume, we include the volume occupied by the lights and plants.

To calculate the volume, multiply the length x width x height.

In our example with 2 lamps of 600W, this gives 1.20mx2.40mx2x50m which gives a growing volume of 7.20m³. When you know your volume, you have to multiply it by the volume of air to renew per hour.

NOTE: For most indoor gardens without air conditioning or added CO2, the rule of thumb is 1 per minute. In this case, multiply the growing volume by 60 to calculate the volume of air to be changed per hour.

Finally, when a carbon filter is attached to the fan, you should expect a 25% decrease in efficiency. This figure is variable and depends on the manufacture & age of the filter, the length and the power of circulation of the ducts used between the fan and the filter and other factors. To estimate this 25% drop in efficiency, simply multiply by 1.25

NOTE: Using a filter lowers the fan efficiency by 25%.

If we relate the equation to our example of a culture chamber, it gives us this:

[Required air removal capacity (m³/h)] = [Active growing volume (m³) x 60] x 1.25

[Required exhaust capacity (m³/h)] = ((1.2x2.4x2.5)x60) x 1.25

= 540 m³/h

The final result is the minimum required exhaust size. For example: TT 150 Ø 150mm flow 552m³/h.

Result: exhaust fan Winflex VK 200

Pipe Ø 200mm

Air flow: 540 m³/h

If the grow room is in a very well insulated place like a basement, then using this figure should be fine. However, if the grow room is located in a place that is very exposed to heat and natural sunlight, such as an upstairs room or an attic, then the size of the extractor needed should be increased by about 25%.

Growing room located in a bedroom or attic: Frequently, it will be necessary to choose the closest extractor among the choices offered by the WINFLEX VK range. In our case, the closest and widely available is an extractor of size 200mm 780m³/h type VKU 200.

|

|

| Example of cultivation in a basement. | Example of cultivation near a room. |

How to calculate the size and air capacity of the air intractor:

As mentioned above, a continuous supply of fresh air (outside the production area) must be provided in the greenhouse. This can be achieved in several ways:

|

|

|

Make a passive ventilation through which fresh air can be established. (through the open window). Note! As a general rule, the passive intraction should be 2 to 3 times larger than the extraction outlet. |

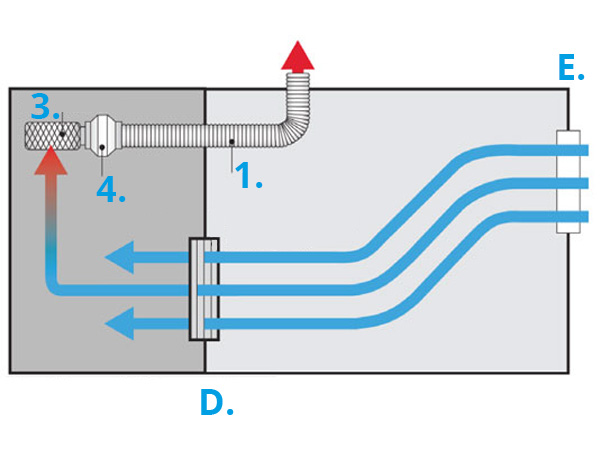

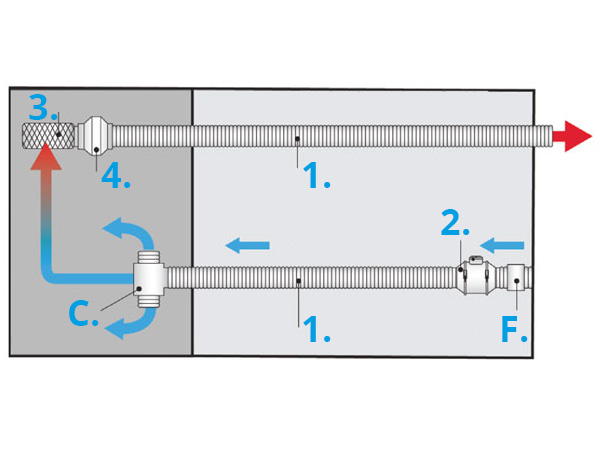

1. Ducts (flexible ventilation ducts) Second way: Make an installation of active in-line fans that push fresh air into the greenhouse. This installation is more efficient than passive ventilation. |

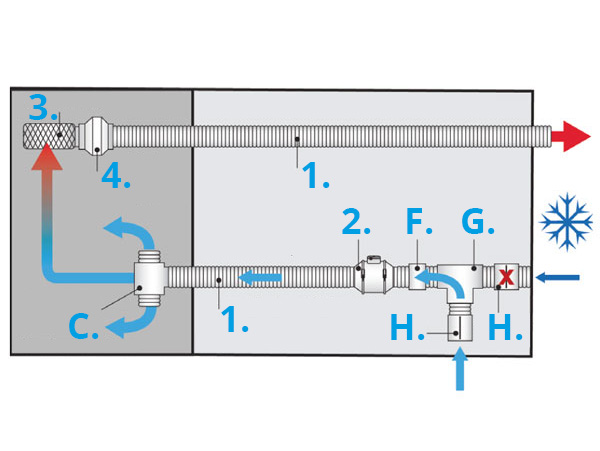

1. Ducts (flexible ventilation ducts) During the cold winter months, it is strongly discouraged to pump air directly from outside but rather to take air from a cool room in the house (the bedroom or living room). |

|

|

|

|

1. Ducts (flexible ventilation ducts) During the summer months it is better to draw in outside air via a cooler (or air from an air conditioner) rather than the air in the house which may be too hot. Source of cool air in summer. Whenever you draw air directly from outside, it is advisable to use a filter box Winflex (with flat filter element) or the Winflex FBV series (with V-filtering element, increasing the filtration of the area) to avoid any intrusion of pests and other insects. |

1. Ducts (flexible ventilation ducts) This means that when positioning your air intraction, it is best to place it near the source of fresh air and push it towards the grow room. To make the air in the greenhouse filtered more efficiently, make sure the flexible air duct is smooth and straight. |

To avoid a backflow of used air, Winflex has provided a series of backdraft valves that open when the fan is turned on and close when it is turned off. This system is installed in line with the series of flexible ducts Winflex.

Note: When installing a vacuum extractor, it is imperative to ensure that it provides the necessary air to the surface

If you introduce more air than the exhaust fan can remove, the air begins to build up and causes a "positive pressure" that exhausts the untreated air out of the grow room. Thus, select an exhaust fan with a maximum air capacity and flow that is 10-20% lower than the actual exhaust fan outlet to create "negative pressure".

To find the intractor diameter, you will need to take the extractor capacity and apply an estimated reduction for the carbon filter - 25%. If our goal for the intractor is 15% less flow than the extractor, we need to multiply the reduced output by 0.85. Below is a model to gauge the room's inlet fan for example with 2 x 600W lamps.

Below is a diagram showing how to "measure" the intraction needed for a room with 2 lamps 600W:

[Estimated capacity air extractor with carbon filter] = [Air extraction capacity] x 0.75 = 585 m³/h

[Fan air inlet capacity (with reduction to provide negative pressure)] = [Estimated air extraction capacity with carbon filter] x 0.85 = 497 m³/h

For this intraction rate, the closest product in flow rate and widely available is a size 150mm type TT150 or VK150

Note: When installing the intraction, make sure that the air extractor is installed opposite the growth chamber.

Useful tips for improving ventilation in your grow room

|

|

|

1. Ducting (flexible ventilation ducts) Position your air intractor downward, diagonally opposite the exhaust. Remember, you must mount your fan. This will allow a new stream of fresh air to circulate through your grow room, while removing the warm, moist air at the same time. When mounting your exhaust fan, use the proper brackets to avoid vibration (Winflex TT and Winflex VK series fans are supplied with mounting brackets). You can also use the fan Winflex. The exhaust should be installed diagonally and opposite to the air intraction for better air circulation and evacuation of warm and humid air. |

3. Carbon filter

|

|

|

|

5. Muffler The use of silencers (Winflex SR, SRF or SRP) and acoustic ducts (Winflex) significantly reduces the noise caused by airflow in the ventilation system. If noise is a major concern, consider using soundproof ductwork. This can eliminate up to about one-third of the noise generated by air turbulence. It is necessary to use at least one meter on both ends of the extractor to get the full benefit. Use noise silencers, either rigid (Winflex sR series) or flexible (Winflex SRF SRP series) is also a good way to reduce noise. They can be used to run a ventilation system in a domestic space. Again, for best results, attach a muffler to each end of your fan. This will help reduce the noise level by up to a third. |

6./7. TTU and VKU: Intake and exhaust with fan speed control Use fan intake Winflex TT ... U and exhaust fan Winflex VK ... U with speed and temperature control module to obtain better temperature and air quality conditions. To obtain a precise control in hot and cold climate, it is interesting to use the extractors, intractors with automatic speed control and temperature sensor of the extraction duct (Winflex TT ... U series and Winflex VK ... U series) or with the remote control 4 temperature sensors 2m long (Winflex TT ...) These fans run at a permanently low speed. Regular air changes are essential for good growth. A built-in combination speed control and thermostat will allow you to regulate the number of air changes per hour. It will also compensate for hot and cold temperatures by increasing or decreasing the airflow when triggered by the temperature sensor. |

CAUTION: Heat generating equipment should be stored outside the grow room.

To ensure electrical safety and avoid unnecessary heat transfer, any equipment that generates heat should be stored outside the grow room on a shelf or other non-flammable surface.

Nutrient storage, all liquid nutrients, fertilizers and additives should also be outside your grow room

Find all our tips for your indoor growing :

- Indoor growing tips : Light

- Tips for indoor growing : Air

- Tips for indoor growing : The Substrate

- Growing tips for indoor plants : Water and fertilizers

- Growing tips for indoor plants : Germination and Cutting

- Growing tips for indoor plants : Growth

- Growing tips for indoor plants : Flowering

- Growing tips for indoor plants : The growing room

- Tips for indoor growing : Systems

- Growing tips for indoor plants : Water control

- Growing tips for indoor plants : Aquaponics

- Growing tips for indoor plants : Accessories